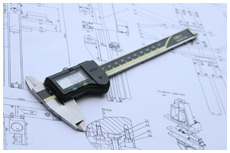

Manufacturing possibilities

Own manufacture

The most of metal‑working, tool-making and locksmith operations are provided by our own machinery. We perform milling with conventional and CNC milling machines, turning, drilling and thread cutting, material separation, electroerosion machining with a wire cutting machine, flat grinding of metals and we have also an equipment for microimpact marking available. At the current time we are able to mark metals up to hardness of 64HRC, wood, plastic materials and glass. Our manufacturing possibilities also include processing of metal sheet, welding (CO, plasma, oxy‑acetylene) and slot perforation of plastic tubes.

Generally, we are able to provide everything from primary inputs by means of a wide range of our manufacturing machinery technologies. In such a way, finally we are able to produce the complete set of sub-assembly groups and final assembly groups, including thermal treatment and surface treatment on the customer’s wish.

Cooperation

In cooperation we are able in combination with our own manufacture to provide erosion of metals, galvanization of metals (zincing, nickeling, blacking, chromizing), hardening of metals (cementing, nitridation, tempering), surface treatment (comaxit), CNC turning and forging operations.

Materials

The following material types are machined most often:

The following material types are machined most often:

- steel in the whole quality range – classes 11-19

- stainless metals

- aluminium

- brass

- copper

- cast steel

- plastic materials (Zedex, Murdfeldt, etc.)

"We provide our customers sophisticated solutions which support stability and efficiency increasing of the manufacturing process."